I’d like to give a quick summary of where we are at with the

last few blogs.

In my recent blogs titled: the Insider’s View of TheFoundation Repair Industry , The Dirty Little Secret of the Foundation Repair Industry,

and The Right Solutions for the Right Problems, I established the fact that

most buildings built in an arid environment tend to have heaving problems

instead of settlement problems, close to 80%. I also established that many (I

estimate up to 50%) foundation problems get misdiagnosed by foundation

contractors and even some engineers on a regular basis. I also discussed that

the typical industry repair methods for remediating misdiagnosed heave are

wrong and counterproductive.

In my subsequent blogs entitled The Insider’s View of theFoundation Repair Industry Part 2, and Deflection vs Tilt What is theDifference?, I discussed the due diligence that is required in order to

properly diagnose a failing foundation. Without going through the hard work and

diligence required, mistakes are likely to happen.

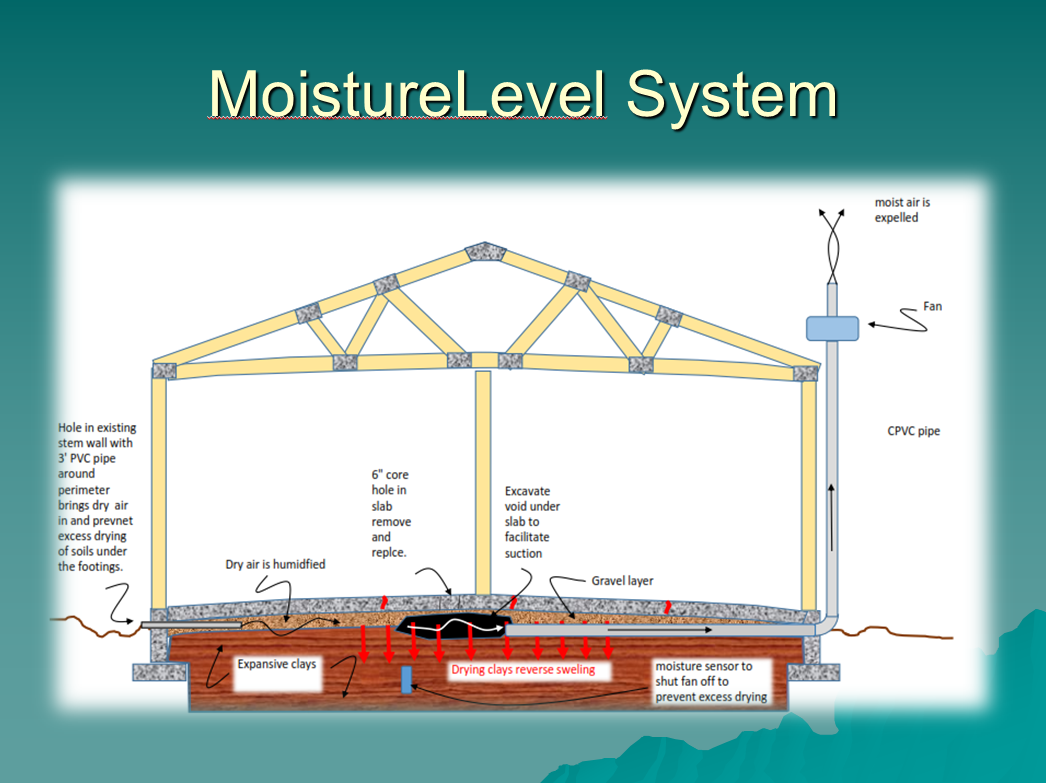

In my last series of blogs entitled, How to Remediate aHeave, and MoistureLevel Smart Foundation System for Expansive Soils, I

discussed a new revolutionary way to mitigate the effects of expansive clays on

existing foundations and floor slabs. I have developed this method and patented

it so that I can have something of value to offer homeowners and building

owners with this difficult to resolve problem. It is a unique cost effective

and nonintrusive solution that has very good initial results. In my discussions

with geotechnical engineers and structural engineers for the past for five

months I have received nothing but supportive and encouraging comments for the

system. Not one naysayer.

This system is only about 5% of the costs typically charged

for very intrusive and minimally effective heave mitigation treatments. Let me

repeat that….. 1/20th of the costs! With far superior results! At

the same time it mitigates Radon radiation caused cancers, harmful gases (VOC’s

and PCB’s from pollution), eliminates wet slabs, and a theoretical reduction in

termite infestation.

Stay tuned for more….