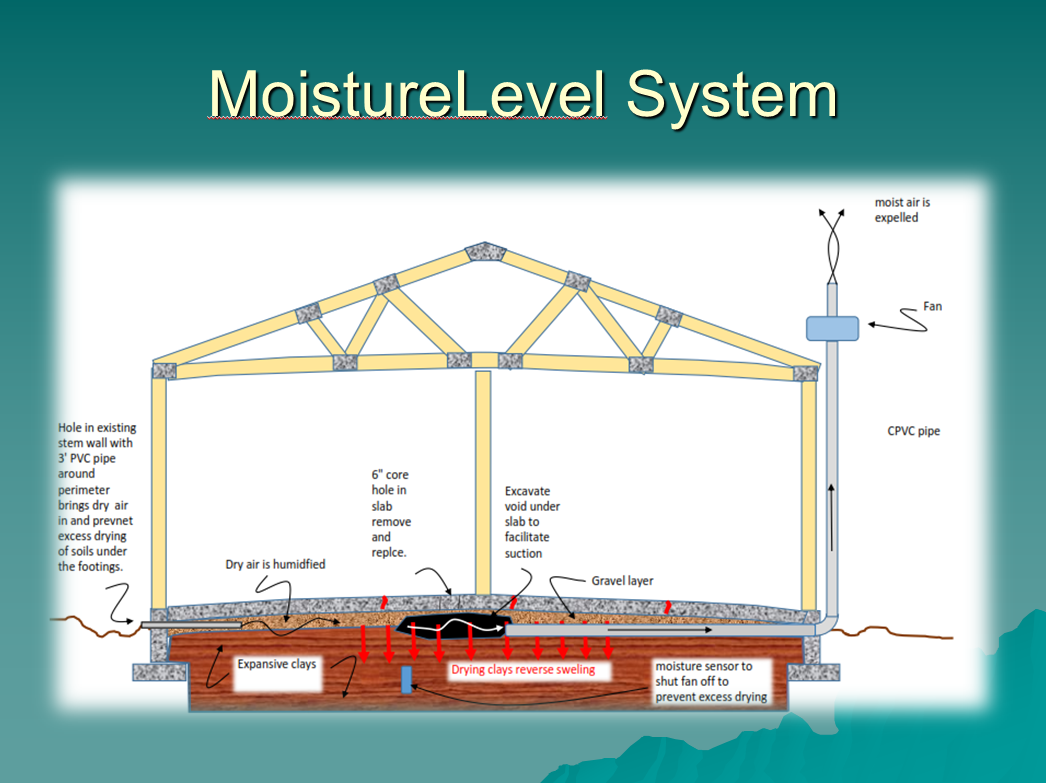

So in my last blogs I discussed the problems facing the

foundation repair industry and a potential solution to those problems with my

moisture level system. So how did I come to develop the system?

Many years ago I was discussing with David Deatherage of

Copperstate Engineering about all the heave problems that we were encountering.

He related to me an experience that he had with an environmental remediation.

He was removing chemical contaminants in the soil that happened to be below a

commercial building. The methodology called for active soil depressurization

techniques i.e. venting to force the chemicals to one end, where they could be

collected and disposed of. This technique also removed the water as a byproduct

of the process. This building happened to be on top of expansive clays and

eventually experienced some settlement. So we thought about it in reasoned that

we could try to use this process in a controlled manner with clays.

We actually experimented on a house in Chandler that had a

severe floor slab heave about 13 years ago. We hooked up a huge commercial

vacuum to some 4 inch PVC pipes and connected them to a whole that we cored in

the slab. We also drilled holes in the stem wall at the level of the ABC around

the perimeter of the house. Very similar to the drawings for my system now. We

measured the humidity of the air going in and coming out and concluded that we

were removing moisture from the soil.

The system was noisy, bulky, and expensive, so we reasoned

that it could not be left at the house on a permanent basis. So then we began

to think that we could leave it there for some period of time but we were

concerned about returning moisture levels in the future. As happens in life we

got busy with other things and did not pay much attention to this for quite a

while. The Economy fell apart and we all became focused on basically surviving.

Fast-forward to about year ago when I was in Omaha receiving

training from our supplier, Foundation Supportworks. I overheard several

contractors discussing how they remediate Radon. And low and behold it was very

similar to my experiments all those years ago. However with off-the-shelf

technology and lower costs it became feasible to leave the system on-site

permanently removing the issues of returning moisture. The gears now turned in

my head very quickly. I immediately called Dave up again and re-discussed with

him. We decided to install some systems using these off-the-shelf components

and some feedback mechanisms to control the moisture content.

The rest as they say is history. We have now installed on

over 15 homes with an average of one or two week now being installed. We are

closely monitoring these homes. The very first one that we installed showed a dramatic

drop in the heave of over ½ inch in a six-week period of time. I was astounded.

I never expected such good results in such a short period of time. I have

shared now with the geotechnical engineering community and received an

overwhelmingly positive and supportive response.

More to come. Stay tuned.

No comments:

Post a Comment

Let us know your thoughts... leave a comment