Join the discussion here!

As more homeowners are starting to realize the advantages of

having a foundation inspection that is scientific, objective, and thorough,

using industry standards, and engineering oversight, the industry is struggling

to adapt to these expectations.

I received a phone call the other day from a distraught

homeowner. Lets call her Mary. Mary shares a common wall with her neighbor. Like

her neighbor, she noticed signs of foundation movement…. Cracks in drywall,

sloped floors, and door and windows out of square. A month or so earlier we

completed one of our engineered foundation investigations on her common wall

neighbor, and Mary was impressed with

the report and felt like she needed to have her foundation investigated as

well.

This is where Mary gets a little sideways. She logically

assumed that she could get something comparable from another foundation repair

contractor and thus get in effect a 2nd opinion for both properties.

So she had paid for an investigation and waited.

To her chagrin, (according to Mary) a representative showed

up and delivered a quote to have geotechnical borings done on her property for

$4500. That’s it. Nothing more. I have the greatest respect and admiration for

geotechnical engineers and value their input on almost daily basis. But this is

not the place to start on a foundation investigation.

According to the Foundation Performance Association and the

Texas Chapter of the American Society of Civil Engineers, there are 3 basic

levels of a foundation assessment. In short they are:

. A.

Visual look around and observation of key

critical factors (see the document for those factors)

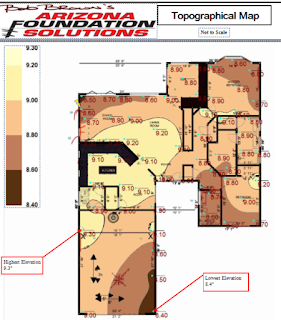

B.

Manometer survey, damage map, aerial photos,

tilt and deflection analysis (as the main items)

C. Full investigation including borings,

petrogrphical analysis, Review of all available records and

reports and many

more in-depth items.

Level C is usually reserved for legal or insurance cases. Level

A is basically to see if there is anything worth investigating. Level B is where most of the work is done.

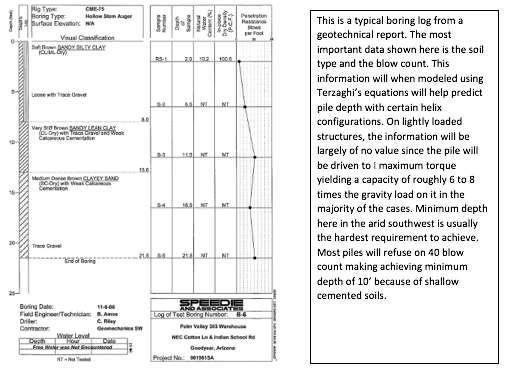

Because helical and push piles return soil information that

is valuable feedback on soil properties, borings have a limited value on

lightly loaded structures as long as the safety factors are high enough to

compensate for uncertainty (say like 6 to 1) . Sometimes borings can help with

diagnosis when the data on a level B investigation is contradictory, confusing

the interpretation. This is fairly rare. From my experience maybe .5% of the

time. (1 in 200).

I hope that the industry in general learns to conduct

scientific investigations that are objective, and thorough, using industry

standards, and engineering oversight. Even if it means they become better

competitors. In the meantime know what you are getting before you pay for it.